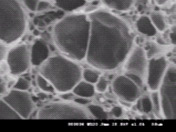

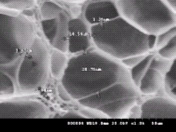

The basic materials of our floats are NBR and phenolic resin, through two steps molding process, molded hole, internal structure is a closed-cell, homogeneous structure, and outside layers is a hard, smooth outer surface This can protect the cell structure and adds to the mechanical strength of the part

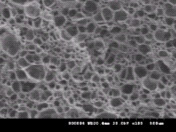

| Cross Section View of Float-honeycomb Shape Cells (Magnified 100x) | Cross Section View By S.E.M. (Magnified 1,000x) - Independent Cell Structure Can be Seen - | |

|

|

|

1) Product Specification

Our floats is a closed-cell material, Unlike hollow floats, they are not subject to sudden failure

Being able to resist most fuels, oils, aqueous solutions, solvents, and chemicals. Special to methanol and fuel mixtures.

Using molded hole technology, better than drilled hole.

Can mold floats into complex shapes per customer requirement.

Being able to design different density range floats per customer requirement

Ring magnets and metal or plastic inserts can be molded in for accurate level sensing.

Low sulfur releasing (<5 ppm), not damage silver plating sender cards.

2) Density

NBR floats are available in two general density ranges; * 160~190kg/㎥ (10-12lbs/ft3) * 285~320kg/㎥ (18-20lbs/ft3) Special density range can be met by custom molding.

3) Operation Temperature

Our floats are recommended to use from -60°C to +120°C.

By special processing, floats can be post cured to operate in a 150°C environment.

4) Operation Pressure

Our floats can resist pressure up to 2MPa or higher,

Depending on: shape and size of the float, density, operating temperature, and the fluid in which it is used.

Site Map | E-mail | Links | About Us | News | Products | Quality | Contact Us

Copyright© 2014 www.cp-float.com All Rights Reserved. Chempoly (Suzhou) Rubber & Plastic Co.,ltd,